Compressed Knitted Mesh Gasket with excellent shielding performance is widely used in the magnetic fields for EMI/RFI shielding. It can shielding the electromagnetism through sealing the gap of equipment and machines.

Compressed knitted mesh gasket can be made of various different materials, including: stainless steel, monel, nickel, aluminum 5056, tinned copper steel, brass and other materials. The specific metal alloy materials make compressed knitted mesh gasket can stand the extremely high temperatures, corrosion and other hostile environments. The diameters of compressed knitted mesh are commonly 0.11mm to 0.13mm and special specifications can be customized.

Stainless steel compressed knitted mesh gasket.

Tinned copper steel compressed knitted mesh gasket.

Brass compressed knitted mesh gasket.

Aluminum compressed knitted mesh gasket.

Compressed knitted mesh gasket can be made into various different shapes to suit the machines and other equipment. The common shapes of compressed knitted mesh gasket are ring shape, circular shape, stripe shape and rectangular shape. Other shapes can be customized according to customers' requirements.

Ring shape compressed knitted mesh gasket.

Rectangular shape compressed knitted mesh gasket.

Circular shape compressed knitted mesh gasket.

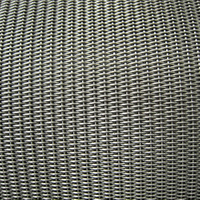

Details of knitted mesh f

Knitted mesh materials: stainless steel wire, copper wire, nickel wire, galvanized iron wire, phosphor bronze wire and polypropylene fiber.

Manufacturing method: Machine knitting.

Manufactured form: Sock/tube (can be slit into a single layer).

Material structure: Inter-locking loops with variable free-space dimensions.

Features and benefit

High filtration efficiency.

High strength.

Corrosion and rust resistance.

Acid and alkali resistance.

Wide range of application.

Knitted mesh with high strength.

Knitted mesh with stable structure.

Applications of knitted mesh

Knitted mesh fabric is widely used in various industries for air and liquid separation and filtration.

Knitted mesh fabric can be used as knitted copper cleaning mesh to clean the inside and outside of the machine parts without hurting the surface of parts.

Knitted mesh fabric can be made into knitted cleaning balls to clean the kitchenware and used in the industries for cleaning applications.

The knitted mesh fabric can be used for eliminate the mist as knitted mesh mist eliminator.

Knitted mesh has excellent shielding performance for cables.

Knitted mesh can be made into cleaning balls to clean kitchenware.

Knitted wire mesh fabric can be used as mist eliminator to remove droplets.

Knitted wire mesh fabric can be used as cleaning mesh to clean the mechanical parts.

Note:

The wire diameters of knitted mesh fabric can affect the flow, dirt holding capacity and pressure drop. In general, knitted mesh fabric with larger wire diameters allow for higher flow capacity but provides lower dirt holding capacity. And the cost of larger diameter is relatively cheap then the smaller diameters knitted mesh fabric. So, you should balance which one is the most concerned and choose the right knitted mesh fabric for your applications.

English

English